On the heels of the Nobel committee’s recognition of the field of attosecond science with the 2023 Nobel Prize in Physics, the NeXUS Facility at The Ohio State University received the NeXUS Laser – a first-in-the-U.S. kilowatt-class laser that will make state-of-the-art ultrafast technology with attosecond to femtosecond light pulses available to users across a wide range of disciplines. …

Semiconductor Day Attracts More Than 400 Attendees to Ohio Union

Semi Foundation Highlights Emerging Careers in Second Annual Event Columbus, OH More than 400 students participated in Semiconductor Day at The Ohio State University, gathering to engage with industry leaders and explore emerging opportunities within the expanding field. This marks the event’s second consecutive year hosted on the university’s campus. “We are proud to host Semiconductor Day at …

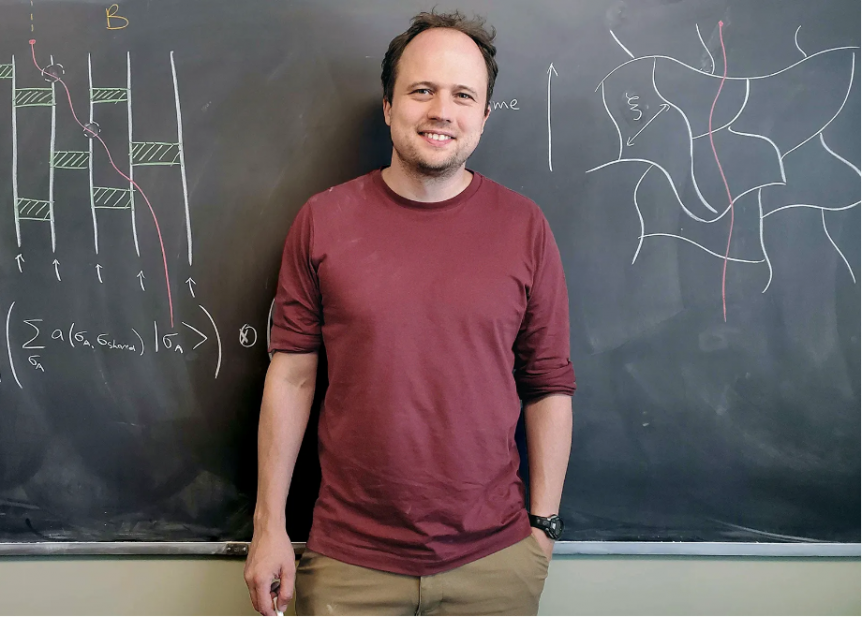

Brian Skinner receives 2024 Early Career Distinguished Scholar Award

Brian J. Skinner, PhD, assistant professor of physics in the College of Arts and Sciences, has earned The Ohio State University 2024 Early Career Distinguished Scholar Award. Senior leadership in the Enterprise for Research, Innovation and Knowledge recently surprised Skinner with the honor during a department meeting. “It feels very touching that so many people put so much effort into …

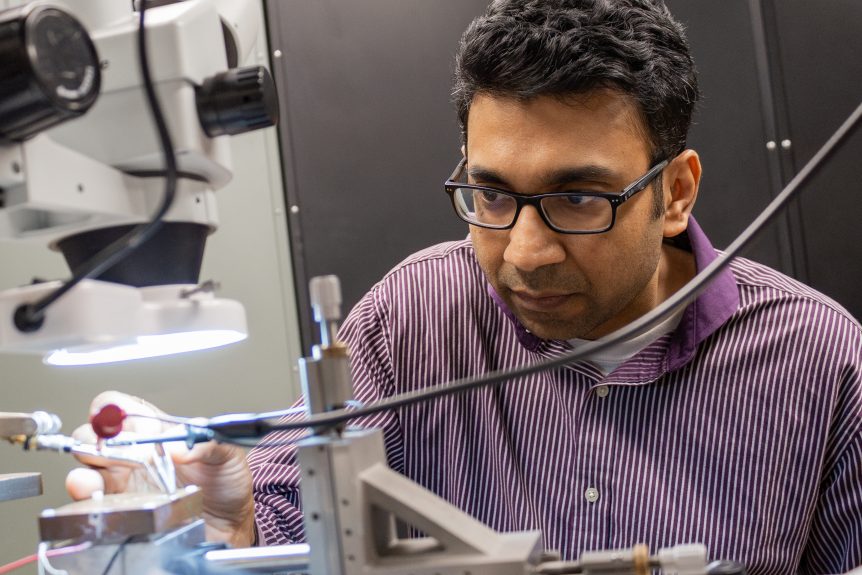

New NSF grant helps IMR-Ireland collaboration spearheading innovative photonics research

The Ohio State University was awarded a significant National Science Foundation (NSF) grant for pioneering research in visible light-wave generation and manipulation. The research has the potential to revolutionize biophotonics with miniaturized, cost-effective photonic circuits that would enhance healthcare diagnostics and treatment. The $425k U.S.-Ireland partnership VIBRANT (Visible Light-wave Generation and Manipulation through Non-Linear Waveguide Technology) was seeded by …

In the news: How Ohio State is partnering with Intel in anticipation of the Central Ohio plant

NBC4 checked in with the Institute for Materials and Manufacturing Research to learn how Ohio State is preparing the future semiconductor industry workforce ahead of the Intel plant launch in Central Ohio. IMR executive director Steven Ringel and Electrical and Computer Engineering doctoral student Manisha Muduli spoke about the Center for Advanced Semiconductor Fabrication Research and Education (CAFE), as well as research …

IMR leadership honored at first Middle East and North Africa Solar Conference

The Institute for Materials and Manufacturing Research (IMR) is helping push The Ohio State University to the forefront of energy innovation through advancements in photovoltaics and battery cell technologies, addressing pressing challenges in sustainable energy solutions. Recently, IMR executive director Steven Ringel was honored as a keynote speaker at the inaugural Middle East and North Africa (MENA) Solar Conference …

IIT Bombay Prof. Dinesh Kabra joins Frontier Center leadership team

The IIT Bombay-Ohio State Frontier Science and Engineering Research Center has welcomed a new member to its leadership team. Prof. Dinesh Kabra from the Indian Institute of Technology (IIT) Bombay has joined Electrical Engineering Prof. Saurabh Lodha as faculty center leaders from the university in Mumbai, India. Their U.S. counterparts at The Ohio State University are Anant Agarwal, a …

In the news: ‘Ohio State’s CAFE program preps students to work at Intel’

Spectrum News visited Ohio State’s Nanotech West Lab to cover experiential learning efforts through the Intel-funded Center for Advanced Semiconductor Fabrication Research and Education (CAFE) that will grow the U.S. semiconductor manufacturing workforce. Read the article and watch the video here: https://spectrumnews1.com/oh/columbus/news/2024/01/27/ohio-state-university-cafe- CAFE offers exceptional opportunities for undergraduates to learn through hands-on research experience. Manufacturing internships for students, …

CEMAS commemorates 10th anniversary and looks to future of innovation

Students, researchers and leaders from The Ohio State University as well as business and industry leaders recently gathered to celebrate the Center for Electron Microscopy and Analysis’ (CEMAS) 10th anniversary. On January 17, guests came to CEMAS to look back on the impact CEMAS has had in a variety of fields, from materials development to cancer cells. The reception featured …

IMR announces Kickstart Facility Grant awards for Autumn 2023

The Institute for Materials and Manufacturing Research (IMR) is thrilled to announce awards for the Autumn 2023 Kickstart Facility Grants. IMR’s Kickstart Facility Grant Program makes shared campus research facilities more accessible to demonstrate materials-related research results with the goal of strengthening near- term research proposals for external support. Autumn 2023 – Awarded Projects Enzymatic Nanofungicide as an Innovative Food …