NanoSystems Laboratory (NSL) provides users with access to advanced material characterization and fabrication tools for research and development applications. NSL operates a diverse set of research instrumentation and research capabilities including:

- Focused Ion Beam/Scanning Electron Microscopy

- X-ray diffractometry

- SQUID magnetometry

- Atomic Force/Magnetic Force microscopy

- EDS X-ray microanalysis

- e-beam lithography

- Electron Spin Resonance spectroscopy

- Physical Vapor material deposition

- ion milling

- ICP/RIE etching

- maskless photolithography

- Low-Temperature/High Magnetic field magnetotransport measurements

- diamond CVD growth

- material polishing

- Kerr microscopy

- critical point drying and magneto-optical material studies

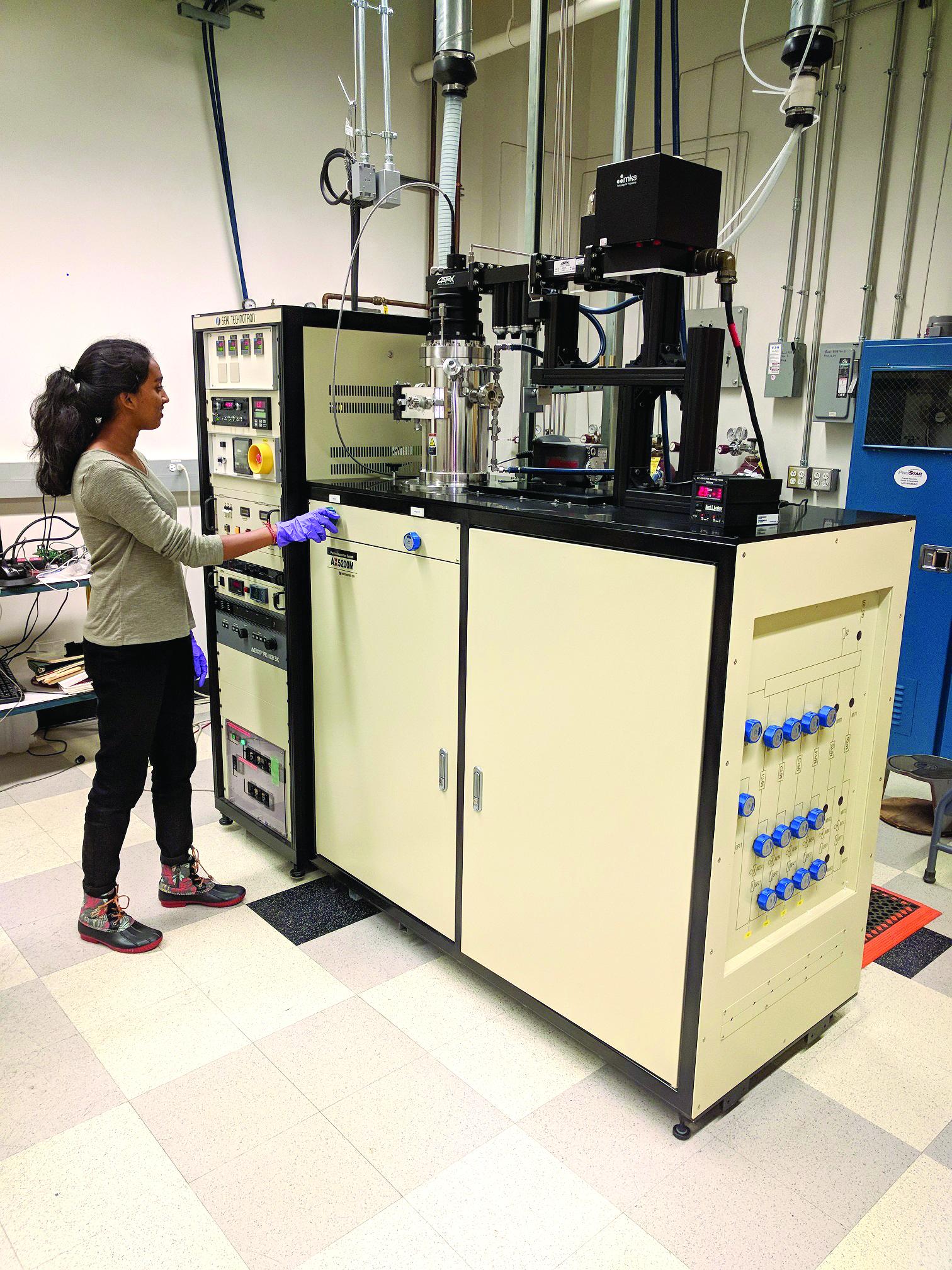

NSL also operates two 1,100-square-foot clean room facilities. One clean room houses instruments for material deposition and processing for photo/e-beam lithography, while the other clean room is devoted to processing organic spintronic devices, and other air and moisture sensitive materials. It is equipped with four interconnected gloveboxes with Ar and N₂ atmosphere. In FY20, NanoSystems Laboratory expanded its capabilities through acquisition of a new Broadband 330 GHz Variable Temperature Magnetic Resonance Spectrometer System funded by NSF MRI award obtained by the team of Ohio State researchers led by Fengyuan Yang. The new instrument will allow measurements of material properties in the frequency ranges previously unattainable in a user facility. Final commissioning of the instrument was delayed due to the COVID-19 shutdown, but it is expected to become operational in FY21.