One of IMR’s goals is to develop and establish externally-supported research centers and centers of excellence. It is also critical to our mission that our core research facilities are at the leading edge, operating at peak conditions, and available to the community. Below is a list of the many centers of excellence at Ohio State connected to IMR, such as the Center for Emergent Materials (CEM), an NSF-funded MRSEC (Materials Research Science and Engineering Center) that was IMR’s first developed center of excellence. The section also lists core research facilities that either IMR operates fully, that IMR supports directly through our network of IMR Members of Technical Staff, or that IMR is engaged through our seed grant program and other promotional means. These core facilities are distributed throughout campus, housed in different colleges and are also on Ohio State’s West Campus. IMR works to establish a coordinated network of such facilities that are available to our community.

One of IMR’s goals is to develop and establish externally-supported research centers and centers of excellence. It is also critical to our mission that our core research facilities are at the leading edge, operating at peak conditions, and available to the community. Below is a list of the many centers of excellence at Ohio State connected to IMR, such as the Center for Emergent Materials (CEM), an NSF-funded MRSEC (Materials Research Science and Engineering Center) that was IMR’s first developed center of excellence. The section also lists core research facilities that either IMR operates fully, that IMR supports directly through our network of IMR Members of Technical Staff, or that IMR is engaged through our seed grant program and other promotional means. These core facilities are distributed throughout campus, housed in different colleges and are also on Ohio State’s West Campus. IMR works to establish a coordinated network of such facilities that are available to our community.

The Center for Advanced Semiconductor Fabrication Research and Education (CAFE) is a multi-institutional research and education center focused on advancing the state of semiconductor fabrication for next-generation device technologies and leveraging proven, world-leading research expertise and capabilities available within our team.

The Center for Automotive Research (CAR) is an interdisciplinary research center focusing on energy, safety and the environment to improve sustainable mobility. IMR and CAR have multiple joint activities, including M&MS faculty hiring, support of IMR’s new Energy Storage Hub, and collaborative faculty research projects in areas such as materials for energy and sustainability.

The Center for Design and Manufacturing Excellence (CDME) is the manufacturing port of entry into Ohio State for innovative, applied research for product design, technology commercialization, and manufacturing for industry. Through the translational interface of the IMR Innovation Lab, IMR and CDME staff collaborate frequently to develop business and joint projects in manufacturing science and innovation. Further, the leadership of IMR and CDME work together strategically to advance Ohio State’s presence and leadership in manufacturing R&D and deployment, identifying and leading major block-funding efforts, and enabling the expansion of manufacturing- relevant national and global partnerships.

The Center for Emergent Materials (CEM) is an NSF MRSEC at Ohio State that engages researchers from multiple disciplines to work in teams on scientific problems too complex for a single researcher to solve. Established in 2008, CEM has three Interdisciplinary Research Groups (IRGs), and focuses on magnetoelectronics at the physics to nanodevice level. IMR is deeply engaged with CEM: first, by driving the process that led to its successful proposal and establishment and, over the years, by sharing in many strategic programs and activities, including the multi-tiered seed grant program, the student poster sessions annually at materials week, the joint support of the Nanosystems Laboratory (NSL), the hiring of M&MS faculty into strategic positions within CEM, and many more interaction points too numerous to list. CEM is perhaps the center we have interacted with the most through the years, as winning and maintaining a MRSEC was IMR’s first primary goal. We are deeply symbiotic, even operationally, through our support of CEM staff and its international collaboration programs. One of IMR’s current associate directors, Fengyuan Yang, is an IRG leader.

The Center for Electron Microscopy and Analysis (CEMAS) is a core materials research facility and one of the largest concentrations of electron and ion beam analytical microscopy instruments for materials characterization. IMR is very deeply engaged with all aspects of CEMAS, similar to our relationship with CEM. CEMAS was partly funded by IMR’s ORSP award – Technology Enabling and Emergent Materials (TEEM), which also provided the position filled by David McComb, who is the CEMAS director and an IMR associate director. IMR provides direct support to CEMAS in the form of an IMR member of technical staff, numerous seed grants to faculty who use CEMAS, and we jointly developed the remote microscopy nodes across the state and routinely share in major proposal development (e.g. NSF NNCI and MRI programs, etc). Several of the IMR’s M&MS faculty work directly toward CEMAS objectives.

The Center for High Performance Power Electronics (CHPPE) is a power electronics laboratory in which researchers exploit the high temperature, high frequency operation and efficiency advantages of silicon carbide (SiC)-based power electronics. IMR identified CHPPE as an area of strategic growth during our M&MS process and, as such, have provided some faculty slots around future power electronics. Therefore, we are deeply engaged, but at the lower TRL levels leading to CHPPE, which is more of a systems-level center. IMR works with CHPPE on industry engagement and several large, external funding opportunities, including from ARPA-E and DARPA.

The Center for Innovation Strategies (CIS) is housed in the Fisher College of Business. CIS collaborates across campus and in the community, as a facilitator and connector promoting innovation at Ohio State and beyond. IMR works closely with CIS in the area of innovation that leads to new products for industry partners and new research centers for the university. CIS is a co-developer of the IMR INNOVATE-O-thon model, and IMR and CIS collaborate thoughtfully and deliberately on innovation models applied across the entire university enterprise and external innovation ecosystem.

Visit fisher.osu.edu/centers-partnerships/center-innovation-strategies

The ElectroScience Lab (ESL) is a major center of excellence in Ohio State’s College of Engineering and one of the largest radio frequency and optics research laboratories in the world. Since 1942, ESL has consistently maintained a national and international preeminence in electromagnetics. IMR leverages ESL faculty, research scientists and students to support innovation events and sponsored projects with our strategic partners in all aspects of electromagnetic and RF technologies.

Innovations in energy storage systems requires integrating diverse knowledge from multidisciplinary teams. Through the Energy Storage Hub, faculty, staff and students who share this vision are dedicated to defining current issues on electrochemical energy storage/ conversion devices, as well as innovating the materials and systems to develop future energy technologies. The Hub is part of the Nanotech West user facility, and a member of IMR’s technical staff coordinates its lab activities. It also serves as the primary lab for two M&MS faculty members.

The Fontana Corrosion Center (FCC) focuses on the study of aqueous corrosion in our effort to develop better methods to protect materials from the adverse impacts of the environment. IMR indirectly works with FCC not at an institute-center level, but more at the faculty support level via our seed and other programs.

The Infectious Diseases Institute (IDI) generates solutions to the detrimental effects of microbes on the health of humans, animals, plants, and the environment for the benefit of society. IMR and IDI collaborate in developing materials and manufacturing solutions to achieve a world free from the threat of infectious diseases.

The Frontier Center, a collaboration between IMR and the Indian Institute of Technology Bombay (IIT Bombay), is believed to be Ohio State’s first academic research center shared outside the U.S. It’s mission is to create a global community of researchers, students and industry to build on the strengths of the universities in materials, devices, components and systems to advance the creation and translation of knowledge, and educate students for the global economy to improve the well-being of our world.

This interface connects IMR strategic partners to our faculty, staff and students to create value and deliver impact to meet the needs in the market. The vision of this lab is for innovation to inform research opportunities while serving as a hub for a vibrant, interdisciplinary innovation community. The Innovation Lab is located at Nanotech West, and it is fully operated by IMR.

Lightweight Innovations for Tomorrow (LIFT) is a National Network for Manufacturing Innovation (NNMI) institute awarded to Ohio State, EWI and the University of Michigan, as a public-private partnership that works on advanced lightweight materials manufacturing technologies, workforce education and training programs in this area. Glenn Daehn, IMR Director of Manufacturing Initiatives, has been the spearhead for LIFT at Ohio State. Through their member companies and CDME, IMR is engaged by seeking testing and services agreements, as well as other arrangements suitable for partner companies.

The Mid Infrared Characterization and Application (MICA) Lab houses electro-optical systems to characterize fabricated infrared detectors and imagers. Research in this lab explores advances in both the array and readout integrated circuit (ROIC). MICA is part of the Nanotech West user facility, and a member of IMR’s technical staff coordinates its lab activities.

The Metalorganic Chemical Vapor Deposition (MOCVD) Lab is home to three MOCVD epitaxial deposition systems: a 4” Aixtron system for deposition of As, P, Sb based III-V compounds (2009), a 2” Agnitron custom dual-chamber growth system for III-nitride materials and novel II-IV-nitride materials (2018), and an Agnitron vertical, quartz cold-wall design for the ultra-wide bandgap oxide alloys and heterostructures (2019). Part of IMR’s Nanotech West user facility, the MOCVD lab is the primary growth facility for and is advised by M&MS faculty member and associate professor Hongping Zhao.

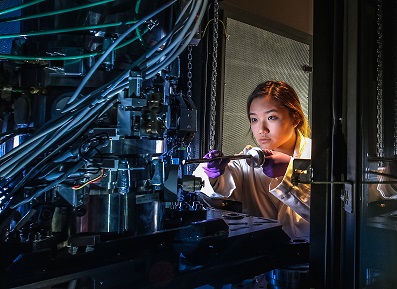

The NanoSystems Laboratory (NSL) is the primary facility for emergent materials. It provides academic and industrial users with access to advanced material characterization and fabrication tools for research and development applications. Research capabilities available at NSL include focused ion beam/scanning electron microscopy, e-beam lithography, nanomanipulation, EDS X-ray microanalysis, X-ray diffractometry, SQUID magnetometry, atomic force/magnetic force microscopy, low temperature magnetotransport measurements and Langmuir-Blodgett trough monolayer deposition. NSL is also a member of the IMR network of laboratories, and directed by a member of the IMR technical staff.

Nanotech West Lab (NTW) is IMR’s core materials research facility and the largest nanofabrication user facility in the state of Ohio. It is a shared user facility supporting both academic and industrial users. NTW provides its users access to a range of material synthesis, fabrication, characterization, and metrology equipment to support a diverse range of materials related research. With 24,000 square feet of lab space, NTW is home to the class 100 nanofabrication clean room, the Metalorganic Chemical Vapor Deposition (MOCVD) lab, the Mid Infrared Characterization and Application (MICA) Lab, the Energy Storage Hub, and IMR’s Innovation Lab. As a university unit under IMR, NTW is directed by a member of IMR technical staff and its operation is supported by nine additional NTW administrative and engineering staff who provide training, process support and project support to Nanotech’s user base. Three M&MS faculty members are located there. Through a large amount of IMR’s seed programs, the institute directly supports faculty who use NTW, as an essential facility that enables their funded research. It is also home to the IMR Innovation Lab.

The Ohio Manufacturing Institute (OMI) develops industry-vetted policy recommendations to help the state and nation establish a best-practice competitive ecosystem for small- and mid-sized manufacturing enterprises (SMMEs). IMR works with OMI in a number of areas, including participation and support of workshops that shape the future of SMMEs. IMR faculty and staff also serve as co-PIs with OMI staff on federal and state grants that enable diverse, community-engaged learning to collaborate on solving advanced manufacturing issues to help address real-world skill gaps and occupational shortfalls in SMMEs industry sectors.

The Reducing EMbodied-Energy And Decreasing Emissions (REMADE) Institute is a National Network for Manufacturing Innovation (NNMI) Institute public-private partnership. The goal of the REMADE Institute is to reduce the cost of technology essential to reusing, recycling and remanufacturing materials such as metals, fibers, polymers and electronic waste, as well as improve overall energy efficiency 50 percent by 2027, saving billions in energy costs. IMR and the M&MS Discovery Theme have shared in Ohio State’s contribution, based on expected participation in consortium projects — two of which have been awarded.

The Semiconductor Epitaxy and Analysis Lab (SEAL) is Ohio State’s primary facility for molecular beam epitaxy (MBE) and is located within the 4,000-square-foot Dreese Lab Cleanroom (DLC). SEAL can provide epitaxial growth of crystalline layers, heterostructures, nanostructures and device structures in a variety of material domains. It is a staffed user-based cost center within the College of Engineering and Department of Electrical and Computer Engineering. SEAL is also a member of the IMR network of laboratories and operated by a member of the IMR technical staff.

The Simulation Innovation and Modeling Center (SIMCenter) is an interdisciplinary research center for the virtual simulation and modeling of product performance and manufacturing processes. IMR leadership is working closely with the SIMCenter to develop joint research projects in which materials and computer-aided engineering techniques intersect at the design and manufacturing of advanced product and production concepts.

The Sustainability Institute (SI) integrates, supports and leads sustainability across the university. IMR and SI collaborate at the intersections of materials, manufacturing and sustainability to enhance our interdisciplinary community, research and innovation. This includes working together to develop new public- and private-sector partnerships and unique experiential learning programs.

The Translational Data Analytics Institute (TDAI) creates and applies data analytics solutions to issues of global importance in partnership with the external community, while advancing foundational data science theories and methods. IMR and TDAI collaborate on the hiring of joint faculty possessing data science expertise that expand our interdisciplinary materials research community.

The mission of The Ohio Agricultural Research and Development Center is to enhance the well-being of the people of Ohio, the nation and world through research on foods, agriculture, family and the environment. The interaction between IMR and OARDC stems from IMR’s Ohio Research Scholar Program (ORSP) – Technology-Enabling and Emergent Materials (TEEM). IMR supported the position for the hiring of Katrina Cornish into the Department of Horticulture and Crop Science (adjunct in Chemistry and Biochemistry). We continue to work with OARDC indirectly through Dr. Cornish and have supported multiple proposals and seed programs benefiting OARDC in the area of agriculture-based biomaterials and bioproducts.