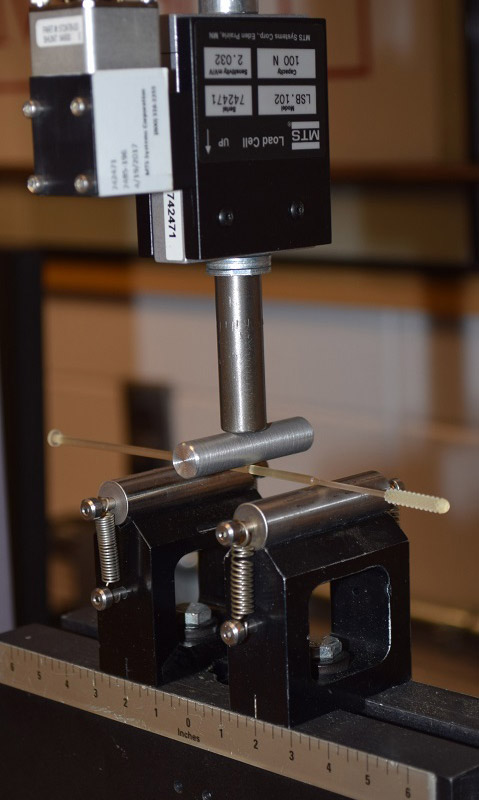

Three-point flexural test. Photo courtesy of MSE.

Teams across The Ohio State University are coming together to combat shortages of critically needed supplies for COVID-19 testing throughout Ohio.

Researchers in the Department of Materials Science and Engineering are analyzing the material performance of the nasopharyngeal swab prototypes being designed for use in detecting the virus that causes the new coronavirus disease.

The Institute for Materials Research (IMR) is leading that collaborative effort, working with partners to manufacture and deliver 3D-printed nasopharyngeal swabs to the Ohio State Wexner Medical Center, which is partnering with the Ohio Department of Health to increase the availability of supplies needed for testing citizens for COVID-19. IMR is working with the university’s Center for Design and Manufacturing Excellence (CDME), the Infectious Diseases Institute, the medical center, and others.

The newly developed swabs are long and thin with a textured top. Health care providers use them to swab a person’s nasal cavity, then send each sample to the lab in a vial of transport medium where it is tested to see if the virus is present.

The Materials Science and Engineering team has been performing mechanical tests on the prototypes since April 23. Laboratory supervisor Pete Gosser manages the mechanical testing.