Dr. Yael Vodovotz joined The Ohio State University Department of Food Science and Technology as an Assistant Professor in 2000, and has been working on physico-chemical and molecular properties of foods. Dr. Vodovotz received her tenure and promotion to Associate Professor in 2006.

Dr. Yael Vodovotz joined The Ohio State University Department of Food Science and Technology as an Assistant Professor in 2000, and has been working on physico-chemical and molecular properties of foods. Dr. Vodovotz received her tenure and promotion to Associate Professor in 2006.

She received her B.S. in food science from the University of Illinois, herM.S. in food science from the University of British Columbia, Vancouver, Canada and her Ph.D. in food science from the University of Massachusetts. Following her doctoral degree Yael held a postdoctoral position at NASA as part of a joint effort between University of Houston and NASA-Johnson Space Center where she worked on various aspects of the Advanced Life Support food system as well as teaching at the University of Houston. Her NASA work continued as an Assistant Professor at Baylor Medical School, part of the National Space Biomedical Research Institute.

Research in Dr. Vodovotz’s laboratory focuses on physico-chemical characterization of biomaterials including foods and bioplastics. In 2007 Dr. Vodovtz received an Interdisciplinary Materials Research Grant from IMR, Assessing the physico-chemical properties of bio-based PLA-PEG films for food packaging applications. Dr. Vodovotz is working with Graduate Student Sunny Modi and collaborating with Dr. Kurt Koelling in the Department of Chemical and Biomolecular Engineering on her research of bio-based materials for food packaging applications.

Characterization of PHBV as a potential polymer for food packaging applications

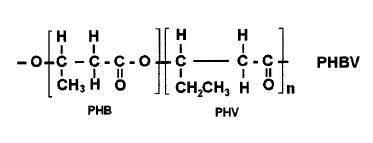

PHB (Poly (3-hydroxybutyrate) families of naturally occurring polymers are extracted from micro-organisms. PHB behaves similarly to conventional thermoplastics, yet are fully biodegradable in common composting conditions. To improve flexibility for potential food packaging applications, PHB can be synthesized with various co-polymers such as 3-hydroxyvalerate (HV), Figure 1. The objective of this study was to characterize the thermal and rheological properties of PHB synthesized with various valerate contents and relate these findings to potential food packaging applications.

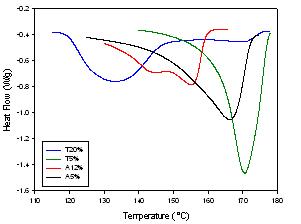

Increased valerate content decreased the melting point of the PHBV polymer (Figure 2). Additionally, the source of the PHBV can result in different melt properties (Figure 2).

Figure 1: Chemical structure of PHBV

Figure 2: Differential Scanning Calorimetry melting behavior of two sources (Tianan and Aldrich Chemicals) of PHB polymers containing different levels of valerate. T20%: Tianan 20% valerate; T5%: Tianan 5% valerate; A12%: Aldrich 12% valerate and A5%: Aldrich 5% valerate

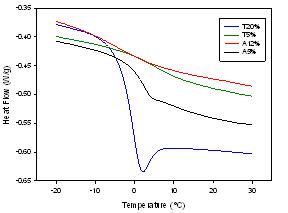

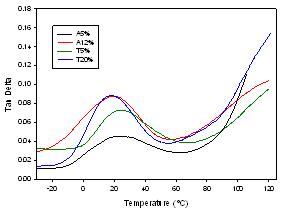

PHBV materials displayed a Tg between -10 to 20 ˚C (Figure 3). Additionally, the damping peak occurred between 15 to 30 ˚C, approximately 20 ˚C above the Tg of the PHBV materials (Figure 4). Such characterization is vital for understanding the limitation of these materials in film packaging applications. It is apparent that commercial PHBV (5% valerate) alone could not be used for film application and a blend is required. Due to Dr. Vodovotz’s findings, PLA/PHBV blends are now being studied for bio-based material food packaging applications.

Figure 3. Differential Scanning Calorimetry glass transition of two sources (Tianan and Aldrich Chemicals) of PHB polymers containing different levels of valerate. T20%: Tianan 20% valerate; T5%: Tianan 5% valerate; A12%: Aldrich 12% valerate and A5%: Aldrich 5% valerate.

Figure 4. Dynamic mechanical analysis (1hz) of two sources (Tianan and Aldrich Chemicals) of PHB polymers containing different levels of valerate. T20%: Tianan 20% valerate; T5%: Tianan 5% valerate; A12%: Aldrich 12% valerate and A5%: Aldrich 5% valerate.

Additional Information

For more information on research by Dr. Vodovotz please visit her webpage.